| ▲ Electronics |

When making PCBs, I normally make the hole sizes on the transparency half the final size, so the copper ring guides the drill bit to the center of the hole, making drilling easier. However, this has a tendency to tear at the copper. The other way is to make the hole full size and optically align the drill bit with the hole. This is done in proper manual PCB drilling machines by having the drill come up from underneath and the user looking down a magnifying lens and crosshairs from the top.

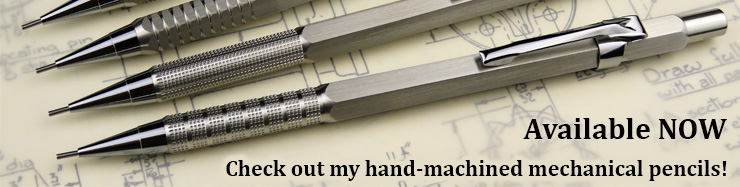

This is a simple attachment for a drill press which does something similar. Using a piece of glass as a partially-reflective mirror, the underside of the PCB to be drilled is illuminated and a magnified image of the underside is visible by looking into the mangnifying lens at the front. A little plastic insert in the top surface (top middle of first photo, blackened with a Sharpie) provides a sharply-defined hole to align the PCB with.

|

|

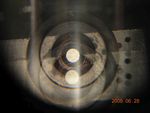

Before drilling hole. Shiny material is underside of PCB board. |

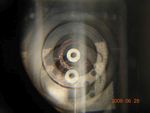

After drilling hole - note good alignment with black guide hole. |

It has a lot of room for improvement, mainly using a proper half-silvered mirror to make the underside easier to see.

| ▲ Electronics |